|

ELMACH - MASZYNY CNC

Wygiełzów 35a 27-570 Iwaniska POLAND |

ELMACH - ODDZIAŁ MOSTKI

Mostki 66D 28-200 Staszów POLAND |

|

OPENING HOURS

Mon-Fri 08:00 - 16:00 |

PHONE

+48 888-027-736 |

|

EMAIL

cnc@elmach.net |

BANK ACCOUNT

PL 04 1140 2004 0000 3302 6845 3852 SWIFT: BREXPLPWMBK |

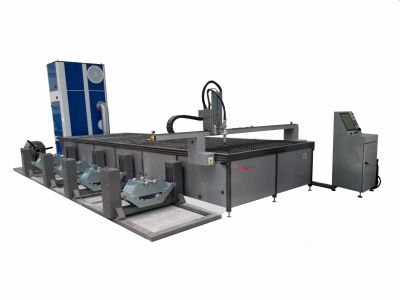

Plasma cutter

COMPACT AHGO+

The plasma and gas cutter Elmach Compact AHGO+ is designed for cutting large pipes with a diameter of up to 800mm and a weight of up to 1500 kg. and the possibility of cutting sheet metal up to 40 mm thick and an area of 2000 x 6500 mm. Designed for companies in the energy industry for cutting pipeline elements and cutting standard details from metal sheet.

Mounted plasma marking module allows for precise marking where the hole must be drilled and then threaded. In addition, the WMS module (water mist shield) enables cutting of stainless steel and aluminum together with a protective film, just like in the case of a laser cutters, and the edges of cut details are free of oxides which may cause weld cracking.

Parameters

- working area: X = od 2000 , Y 6500 mm

- cutting speed up to 6 m / min

- movement speed up to 30 m / min

- plasma cutting thickness: depending of source type

- cutting thickness with an oxygen torch up to:40 mm

Software

The program used to control the operation of the cutter is intuitive and very easy to use.

Drawings of parts can be transferred using a USB drive, or via a network connection, or prepared Directly on the computer at the machine.

Standard equipment

- precise linear guides

- brushless servo motors

- distance of the torch from the material is controlled and set automatically for optimal cutting parameters.

- table with exchangeable bed.

- table with sectional gas extraction and extraction fan (we are using a combination of pneumatics flaps to extract smoke from sections that open only in the cutting area, therefore the exhaust gas extraction efficiency is very high.

- desktop with control electronics

- computer with software

- plasma cutting systems, including sources top brands Hypertherm® Kjellberg Finsterwalde®, Thermal Dynamics

- magnetic anti-collision torch handle

- program for distributing details on a sheet (CAM)

Optional equipment

- gas system with burner, Perun burner, Harris®, Koike®, GCE, etc.

- laser cross lines for better placing the burner on a metal plate

- specialized program for placing details on a sheet, e.g. CutLeader, Wrykrys,

- fume extractor

- compressor

- plasma marking module

- module for cutting with water mist cover

- table with a compressed air - adjustable water level

- table without water level adjustment.

Control software features

- easy to use

- friendly interface with full visualization of the cutting process

- import of DXF, ESSI files

- stopping and restarting the machine from any moment of the cutting proces

- the ability to change cutting parameters during operation

- security system protecting against exceeding the permissible sizes

- sheet metal correction

- database of cutting parameters

- remote diagnostics